Health and well-being are high on the agenda worldwide. The corona pandemic has further strengthened the desire for a healthier lifestyle among many people. Consumers prefer high-quality and natural, but at the same time affordable products. Tablets are, and remain, the most popular product form. Their cost-effective, large-scale production makes them the most economical product on the market.

This high demand is felt by manufacturers like Metagenics Europe. The producer of micronutrients is characterized by an extensive portfolio of products and dosage forms. For its tablets alone, the company recorded a 45 percent increase in demand between 2020 and 2021. In order to meet this demand, Metagenics Europe expanded its production capacities. The motto here was: No compromises on quality!

Forcefully efficient

Metagenics faced a key question with its very popular MetaRelax® tablet: How can the magnesium complex be manufactured in large batches in a reliable manner? Two challenges had to be overcome: Firstly, magnesium salt requires a lot of force during compression, which can lead to an increased error rate, especially at increased production speed. Secondly, the recipe contains many substances that can vary from one batch to the next.

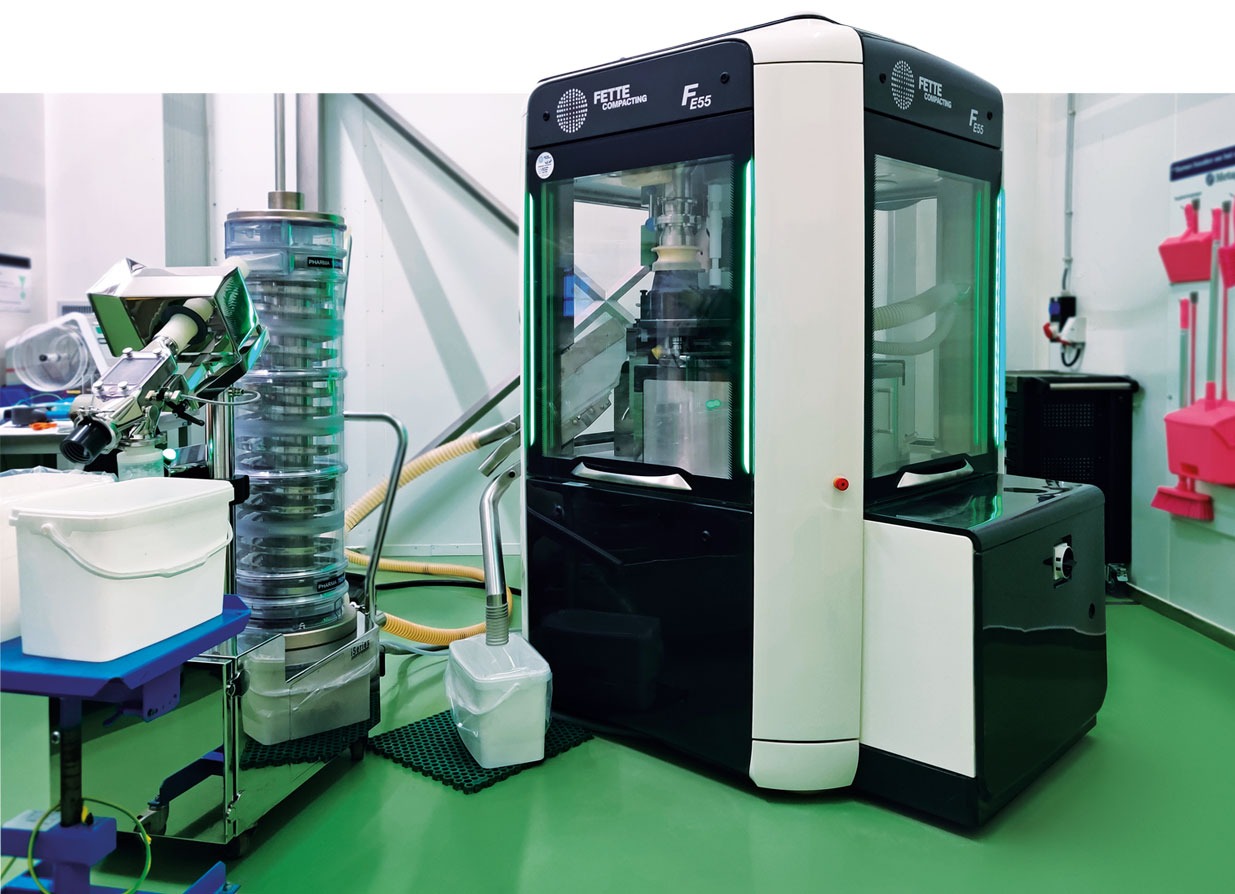

In the search for a technical answer, the company sounded out the market for a tablet press that works powerfully and reliably even at high throughput speeds. Comparative tests showed that the single rotary FE55 tablet press from Fette Compacting runs up to twice as fast as other tablet presses.

Uniform and gentle compression

The machine has been in use at Metagenics since June 2020. The FE55 compresses the ingredients of the MetaRelax® tablets directly, i.e., without upstream granulation. In this process, the quality depends largely on the powdered magnesium salt being processed with sufficient and extended pressure. This longer dwell time ensures more uniform and gentle compression.

To achieve the perfect interplay of pressure and time, the FE55 is equipped with three compression stations. Pre compression and intermediate compression allow Metagenics to produce its tablets in large quantities and at high speed. In combination with the FS19® punches from Fette Compacting, the dwell time is extended by more than 80 percent. In addition to a longer tool life and pressure-holding time, these special punches also allow for smoother running overall, which has a positive effect on the tableting process. The use of segments also plays an important role in minimizing product loss, achieving higher output rates, and reducing changeover times by around 70 percent. In addition, segments with different materials and coatings can be customized for the respective application.

Quality assured

Another decisive factor for Metagenics was that the tablet press should be able to handle varying ingredients reliably. To this end, Fette Compacting developed a special production guide toward adjusting the FE55 to adapt to possible variations in texture and consistently produce tablets of the same quality.

By using these precisely coordinated technologies and services, companies like Metagenics can independently ensure the quality of their production – and thus react at any time to new trends, developments and demands in the dynamic growth market for food supplements.