Schwarzenbek, 5 September 2019 – The tablet is the most widely used form of administration in the history of medicine. This is not likely to change in the foreseeable future, as tablets enable a precise dose, are easy to administer, and are economical to manufacture (storage and transportation). However, the requirements faced by pharmaceutical manufacturers are becoming increasingly complex, while the economic pressure continues to rise.

Thomas Friedrich, Director Product Management at Fette Compacting, explains: “Together with our customers we painstakingly searched for an interface between established production and digital pharma of the future – and rethought our i Series. The current i Series includes the high-performance machines 2090i and 3090i as well as the standard tablet presses 1200i, 2200i and 3200i. These single and double rotary presses provide a high output in the various production tasks with an installed base of several thousand machines worldwide. This is what we are now building on.”

Efficiencyi – meeting of the machine generations

As the next generation of the i Series, Fette Compacting developed a technological platform on which the electrical and mechanical components are based. What’s special about this is that the components relevant for validation are largely retained. “The i Series therefore retains all of its features that make it so valuable to our customers,” highlights Friedrich. “With regard to the machine, Efficiencyi means that the user can retain everything that makes their production successful today in the future – with even higher efficiency and more possibilities.”

The first machine: F10i for small batches

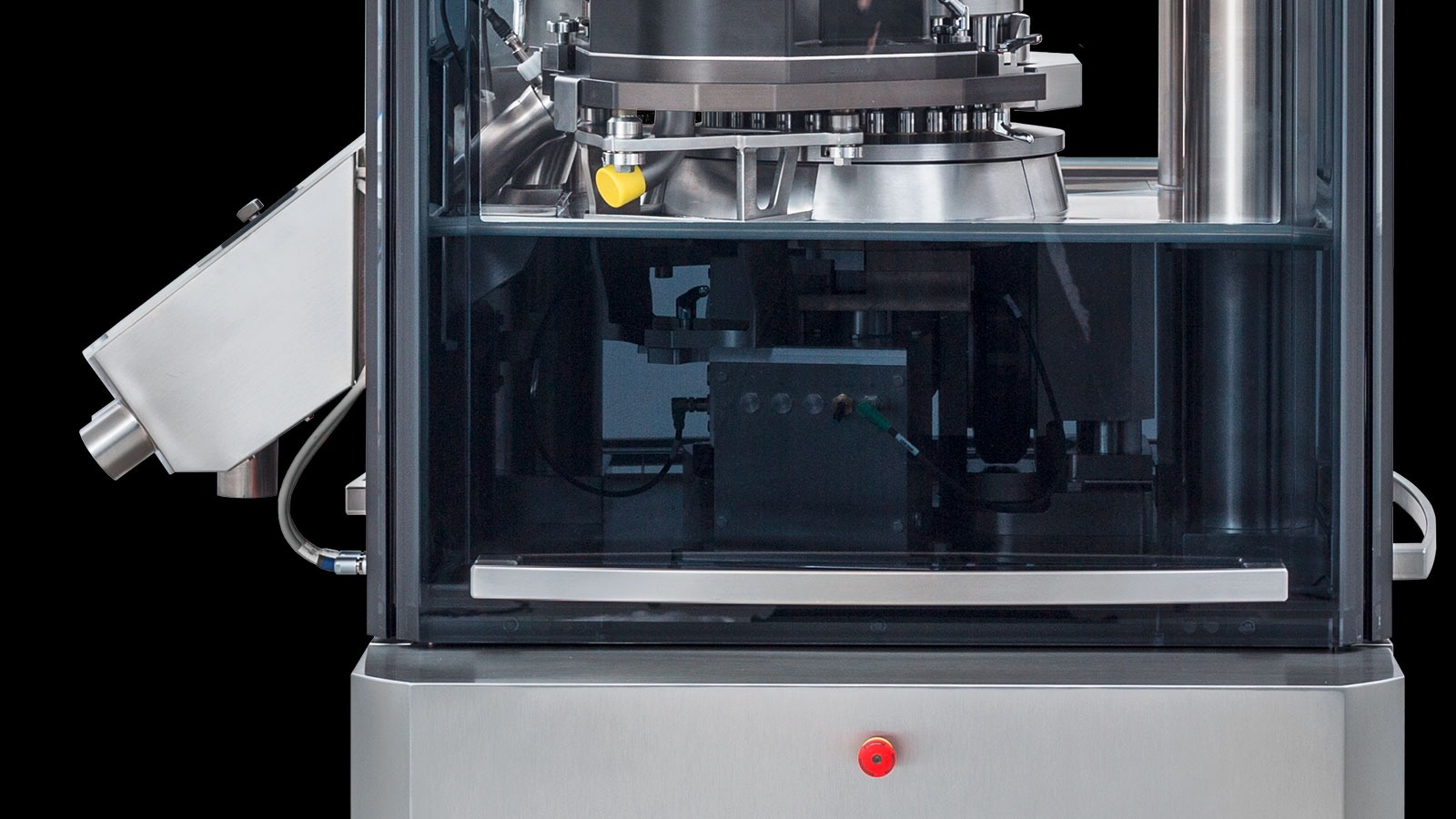

As the first model of the new machine generation, the F10i was presented to the professional public in Schwarzenbek, Germany, on 5 September 2019. The F10i is a flexible, efficient single rotary press for small batches – and optionally also for highly active substances. Producers can quickly adapt the tablet press to different requirements. Flexibility and versatility are also ensured by a handling arm, which supports the operator when changing the turrets, and a mechanical manual turret clamping system.

The most important features of the F10i at a glance:

Innovative: from dust-proof to containment

New, interactive containment solutions save resources and protect employees. The press room design, for example, has been optimized for cleaning and around 50 percent of all enclosure parts have been removed. This reduces the surface of the enclosure parts to be cleaned by around 70 percent. The machine is also dust-tight in a simple version, in order to significantly minimize cleaning efforts and the risk of cross contamination.

Integrative: system-compatible up to IoT and MES

Thanks to the possible system integration, the new tablet presses fit perfectly into existing production environments. As adaptability increases, complexity decreases in many ways. The new i Series features technical connectivity for state-of-the-art production environments, up to “Pharmaceutical production 4.0”. This includes process equipment integrated via plug-and-play and open interfaces for connections to the Internet of Things (IoT) as well as for a manufacturing execution system (MES).

Intelligent: SmartInterface and RFID

Simple and intuitive operation is the key to efficient production. The centerpiece is a server-based real time monitoring, which allows the user to monitor their production processes using mobile devices. “The user can download batch logs at any time and is always kept updated on the production parameters,” explains Friedrich. To increase process reliability even further and avoid tooling errors, the new i Series tablet presses feature an RFID option (radio-frequency identification). The contactless transceiver system allows process components to be automatically identified by the machine so that they can be compared against preset recipes.

Intuitive: tactile HMI and workflow operation assistant

An ultra-modern human machine interface (HMI) supports the user in the form of intuitive control, monitoring, and documentation of the machine and process equipment via a terminal. Tactile feedback, which generates a vibration and a sound when the operating keys are touched, provides added certainty when making entries. At the software level, a workflow operation assistant supports the user to implement workflows safely and error-free.