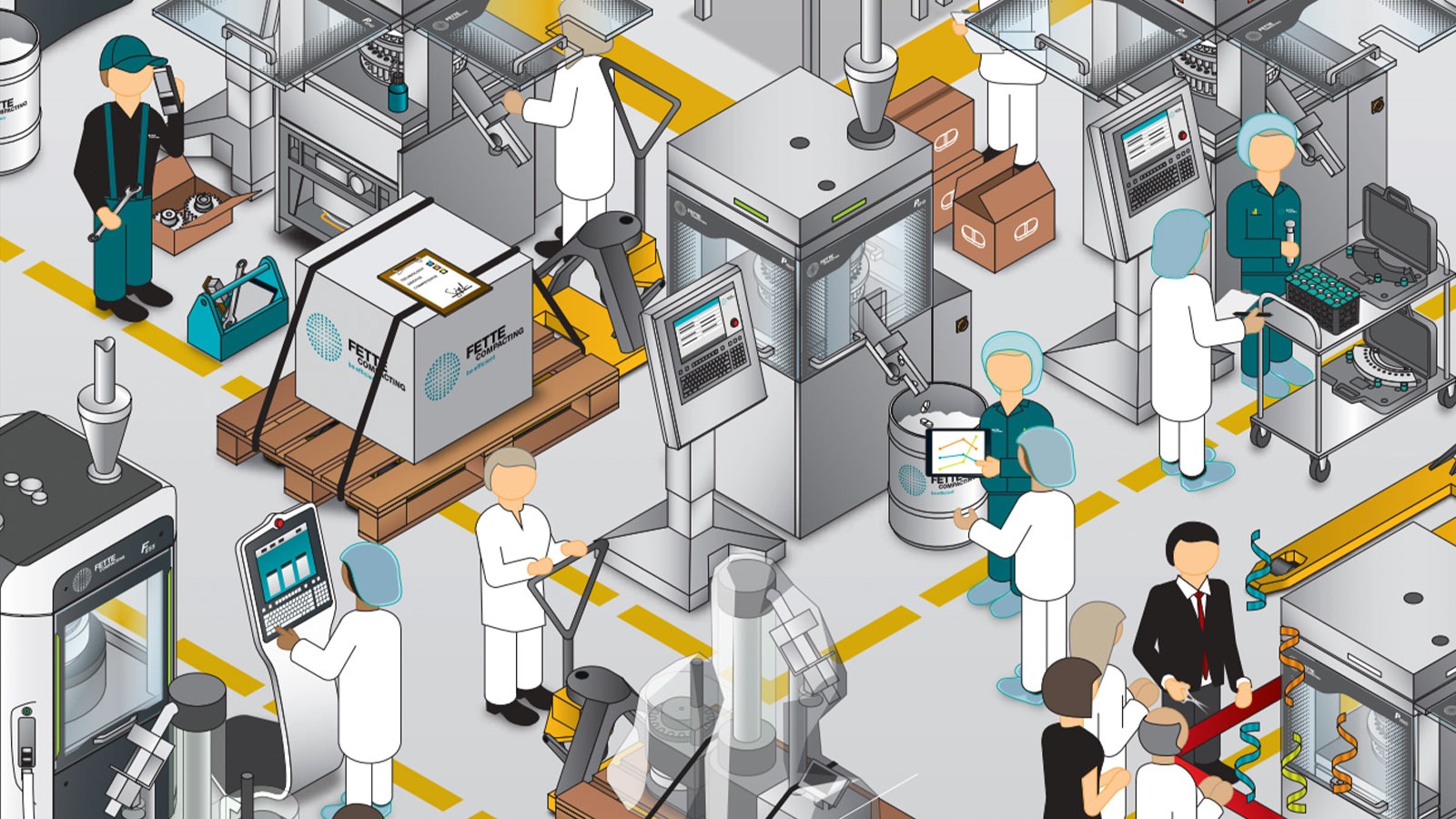

Lifetime Efficiency is double foresight: firstly, it opens our eyes for the entire life cycle of a plant. From development through production to modernization, individual solutions are tailored exactly to requirements during the respective life phases. Secondly, it expands our focus to include the entire production network, across several locations. This approach is similar to fleet management as practiced in other sectors.

Fette Compacting has already demonstrated the potential of this approach for a pharmaceutical manufacturer operating worldwide. “In order to apply the approach at the beginning of the life cycle, we collaborated with the customer to draw up specifications”, explains Martin Davies, Global Account Manager at Fette Compacting. “On the basis of the bundled requirements, the company can control new investments centrally and implement them even faster.”

At the same time, the manufacturer is open to an extensive analysis at key locations in an effort to obtain an overall image of his tableting performance. In this process, Fette Compacting examined various scenarios based on real production volumes and performance parameters. “There were three target scenarios”, summarizes Davies. “First of all, we calculated the possible changeover reduction using existing equipment. Then we replaced the individual machines with comparable new models and planned process optimization and training programs for the operators. The third step entailed a comprehensive redesign of the fleet.”

Less is more – much more

The scenarios led to some very surprising results: for example, it would have been possible at one location to almost halve the number of tablet presses if the customer were to upgrade from an older series to smaller models in the FE series. The highperformance rotary presses which are also easier to clean and refit would reduce overall downtimes in the factory to one tenth. This calculation is confirmed by an in-house study carried out by the customer.

The Lifetime Efficiency scenario also revealed a high savings potential in the area of product losses: “Particularly in the area of expensive special medication, minimizing product loss promised potentials of several millions”, according to Davies. “The long service life displayed by tablet presses often means that a customer‘s machine park was originally installed for an entirely different product mix. This is something which is often overlooked by in-house optimization teams.”

Intensified collaboration

Achieving savings potentials of several millions as in this particular case demands intensive collaboration. Davies is fully satisfied with the teamwork to date: “We implemented the analysis along with our close support on site. Our customer contacts all hold key functions. This way we could always find the right approach and put our teams together in the interdisciplinary compilation that was needed.”

The fact that such cross-departmental collaboration works is also demonstrated by two new sub-projects, according to Davies: “On the one hand, we will provide support in transforming the location in an effort to minimize the efforts involved in validating machine changes. On the other hand, we will draw up a road map for control upgrades to optimize the remainder of the fleet.”

More information can be found here: Lifetime Efficiency.