An international manufacturer of pharmaceuticals wanted to quadruple output in the production of a drug from 100,000 to at least 400,000 tablets per hour. The most obvious solution seemed to be to convert to a multitip quadruple punch. The manufacturer turned to Performance Consulting offered by Fette Compacting and his expectations could even be exceeded by far: the customer actually succeeded in increasing the production volume to 700,000 tablets per hour. As demonstrated by the following example, not only the appropriate tableting tool needs to be selected – companies can only significantly increase output in combination with optimized machine settings and parameters. This requires comprehensive and sound consulting.

“A quadruple punch does not automatically mean quadruple output. This is a major misunderstanding which we try to clarify within the framework of consulting – and yet often exceed expectations all the same”, explains Performance Consultant Jochen Gaeth, who provided consulting services to the customer. The company had been using a 2090i tablet press from Fette Compacting for many years which was optimized for the requirements at production start. The next step was to significantly increase output. This is a trend which has pervaded for many years in the pharmaceuticals sector.

In order to actually achieve improvements using the multitip punch, parameters and mechanical machine settings were adapted specifically. This also involved optimizing the filling unit to enable the four boreholes to be filled sufficiently. This is not automatically the case as a quadruple tool requires four times the volume to be pressed within the same period of time. A further optimization was represented by activating and adapting the special cylindrical height to less than 0.5 millimeters. “Pressing a smaller volume meant that it was possible to achieve such an increase in output with this tool. Even at around 250,000 tablets per hour, the required tablet strength was just about achieved as the forces are distributed across four boreholes. In other words, without our consulting services, the customer would probably not have achieved the desired increase to 400,000 tablets per hour”, according to Jochen Gaeth.

The right combination is decisive

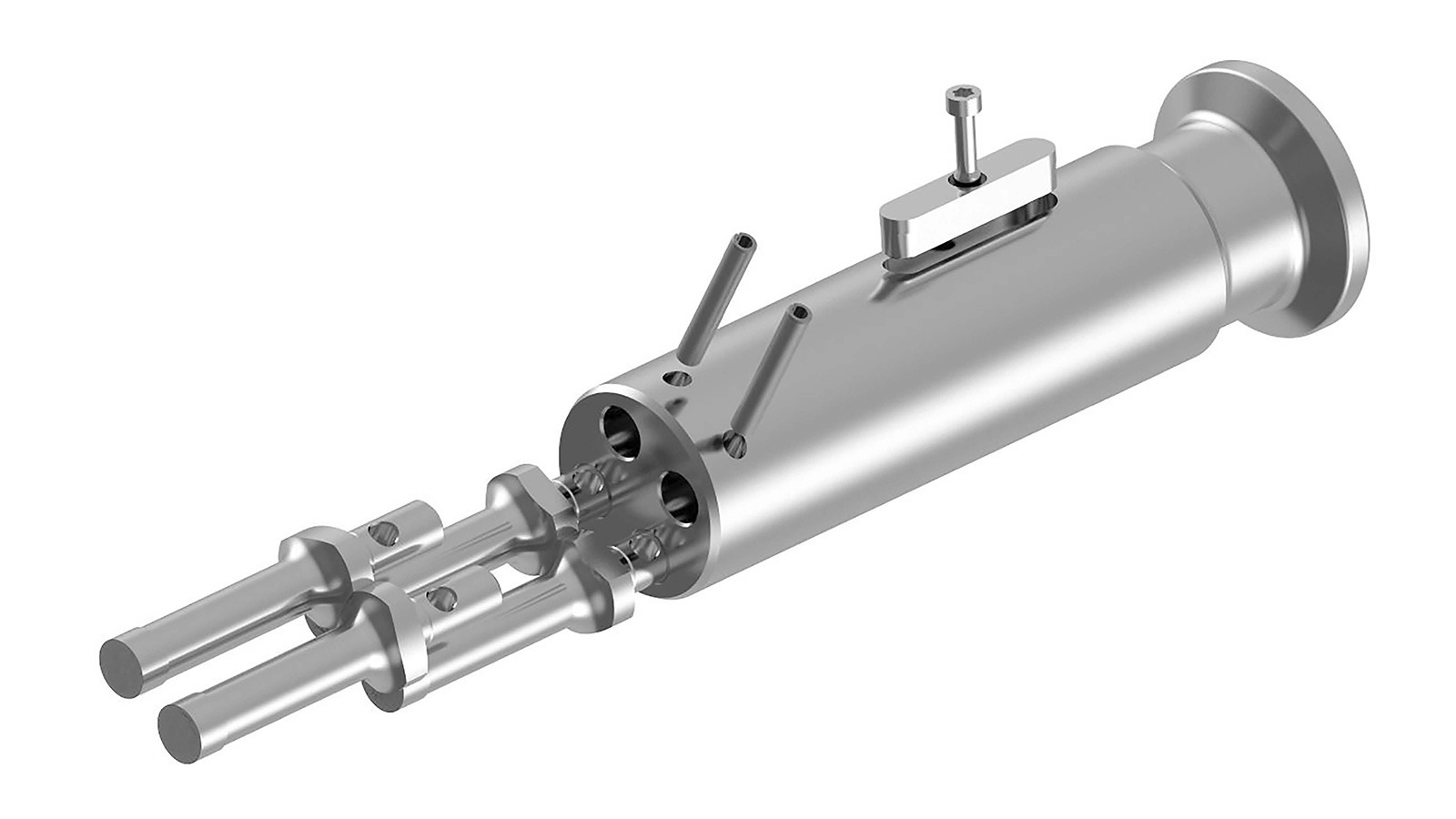

In any case, choosing a multitip punch is only one of many ways to improve output. In most cases, the combination of punch and settings is what counts: “The required output volume of at least 400,000 tablets per hour in this case could also have been realized using a simple tool and our patented FS12® punch, for example”, claims Carmen Ackermann, Product Manager Tableting Tools at Fette Compacting. One fundamental advantage of a simple tool is its easier maintenance and cleaning. Furthermore, each tablet is monitored individually during compression and ejected if necessary. This translates into lower tablet loss.

But the FS® punches also exhibit numerous special features which have a major influence on output. These include an applicationoptimized headform which is somewhat flatter and exhibits a flowing startup performance. Thanks to smaller spaces between the punch heads, more punches can be accommodated than when using conventional tools. This optimizes the overall process: the dwell time increases and running performance is smoother. Wear is also reduced on all components, e.g. on the actual punches and the pressure rollers. This improves tablet quality within a batch and increases production feasibility.

Companies, therefore, are obliged to consider whether a multitip or a simple tool is more effective. A multitip tool usually only pays off if sufficient time is available for maintenance and cleaning which are more complex. These are the types of decisions where support is offered by performance consultants at Fette Compacting.

Patent details FS® Technology:

FS12: EP 2 111 972 B1 und US 8,137,089 B2