December 2022

Measuring like never before (ePAT)

In Continuous Direct Compression, Fette Compacting is also breaking new ground in terms of Process Analytical Technology (PAT). With the FE CPS, it has succeeded in fully integrating PAT sensor technologies. Dr. Anna Novikova, Manager Application Center and Pharmacist at Fette Compacting, has played a major role in this. In this interview, she explains what makes the new measurement system so unique.

Continuous Manufacturing in Flow

The FE CPS guides powder into a continuous flow in a compact, precise and simple way. This opens a whole new chapter of Continuous Manufacturing in tablet production.

November 2022

October 2022

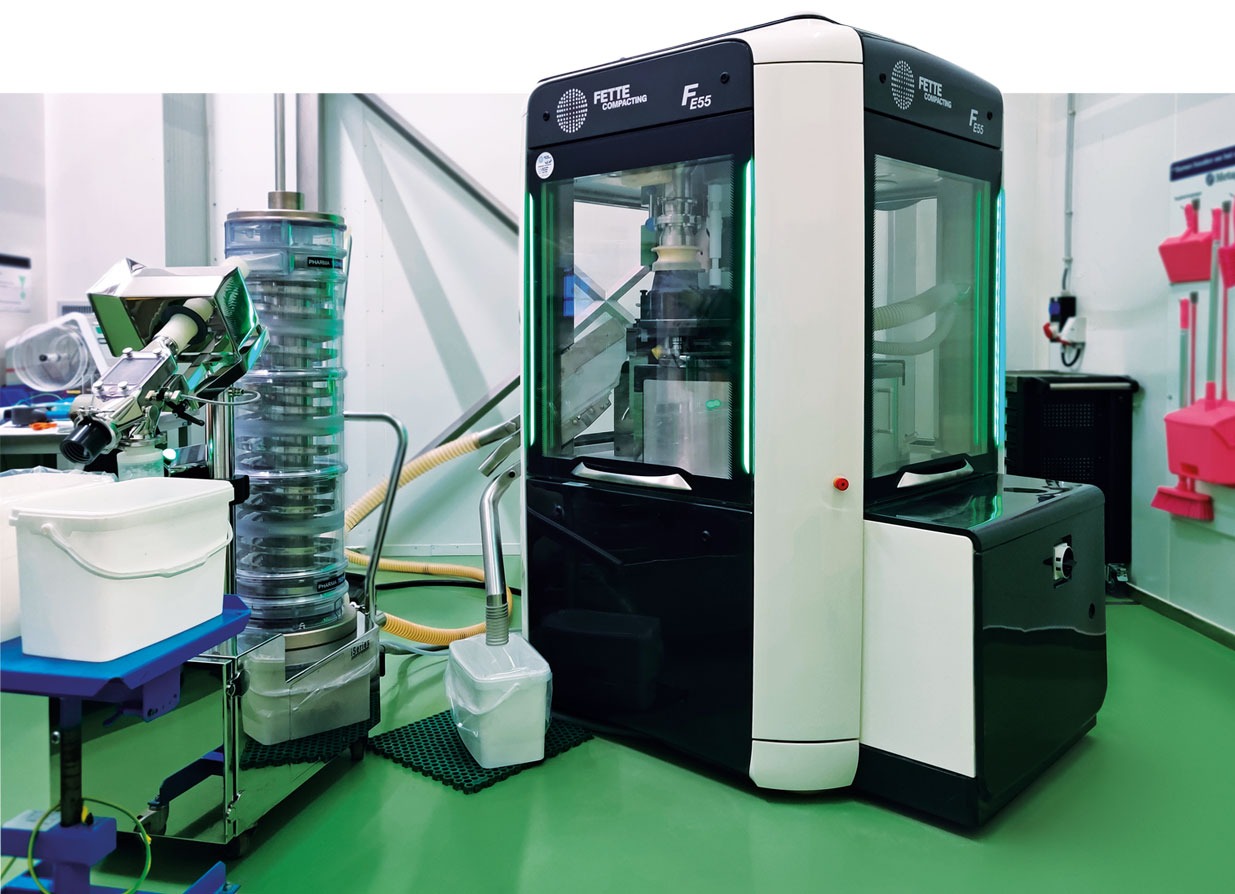

Metagenics Europe manufactures sophisticated magnesium tablets in Belgium. When looking for a high-performance tablet press from Fette Compacting, the nutrition specialist opted for a FE55, as this single rotary press has made it possible to combine high speed and gentle compression.

August 2022

In the form of the F20i tablet press, Fette Compacting is expanding the trend-setting range of the new i Series. This powerful all-rounder is system-compatible, dust-tight and networkable.

The transport, cleaning, preservation and storage of tableting tools play a decisive role in tablet quality. When the tools are not in use, EasyCare solutions offer the best options for handling.

Airbags deploy in a fraction of a second. The fuel tablets from ZF Airbag Germany in Laage ensure that the gas expands extremely quickly - and saves lives in an emergency.

Investment in the future: Fette Compacting enables 17 trainees to start their professional career

July 2022

A new era has commenced in the area of Continuous Manufacturing: Instead of oversized and highly-complex plants, a technology is emerging that focuses on simplicity and efficiency. This game changer comes in the form of the FE CPS.

The new learning app alva from OSDi makes knowledge available around the clock. Using 3D graphics, animations and illustrated instructions, it promotes intuitive learning.

June 2022

Highlighting the Future! Continuous Manufacturing Circle 2022

On June 22 and 23, the future of tablet production was paramount at Fette Compacting in Schwarzenbek. More than 100 participants discussed the opportunities and challenges of Continuous Direct Compression at the "Continuous Manufacturing Circle".

Strengthened presence in North-West Africa

With the opening of a subsidiary in Algeria, Fette Compacting is strengthening its presence in North-West Africa.